-

Las bobinas de los supercalentadores de la caldera

-

Pared de membrana de la caldera

-

Ahorrador de la caldera

-

Tubo de aleta de la caldera

-

tambor de vapor de la caldera

-

El panel de pared del agua de la caldera

-

Cañones de cañones

-

Sobrecalentador y recalentador

-

Calentador Precalentador de aire

-

Sobrecalentador de la caldera

-

AlexanderProveedores confiables

AlexanderProveedores confiables -

LouisHa sido un placer trabajar contigo.

LouisHa sido un placer trabajar contigo.

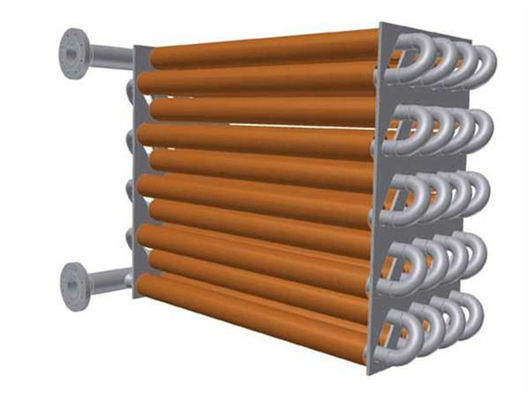

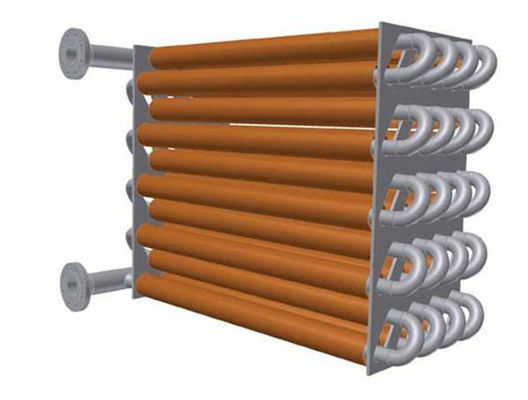

Calderas de gases de combustión Economizador Intercambiador de calor con tubos de aletas para producción de vapor de hasta 120 t/h y 1 año de garantía en circulación natural

Póngase en contacto conmigo para muestras y cupones gratis.

WhatsApp:0086 18588475571

En WeChat: 0086 18588475571

¿ Qué pasa?: sales10@aixton.com

Si tiene alguna preocupación, ofrecemos ayuda en línea las 24 horas.

x| Tipo | Circulación natural | Estructura | Tubos de fuego y de agua |

|---|---|---|---|

| Presión | Bajo/de alta presión | Producción de vapor | Max. 120t/h |

| Estilo | Vertical | Combustible | Carbón / Gas / Carbón / Calor de agua |

| Producción | Agua caliente/vapor | Material | Acero al carbono, acero inoxidable, acero de aleación |

| Estándar de material | Las especificaciones de las normas ASTM, EN o ISO, etc. | Rango de peso | Min: 10 toneladas Max.:1000 toneladas |

| Proceso de fusión | EF+LF + VD | Proceso | Material-> Igot -> Hot/Cold -Rolling-> Tratamiento térmico (Normalización+ templado) -> |

| Estándar de UT | ASTM A388 o EN10228, etc. | Tipo de intercambiador de calor | Economizador de tubo con aleta H |

| Tipo de tubo | tubos de aletas dobles H | ||

| Resaltar | Economizador de la caldera de producción de vapor de 120 t/h como máximo,1 año de garantía para el intercambiador de calor,Economizador de gases de combustión de circulación natural |

||

Los economizadores de calderas son dispositivos de intercambio de calor de alta eficiencia con tubos aleteados diseñados para calentar líquidos (típicamente agua) sin exceder el punto de ebullición del líquido. Fabricamos tres tipos de economizadores de calderas:

- Economizador de tubos lisos

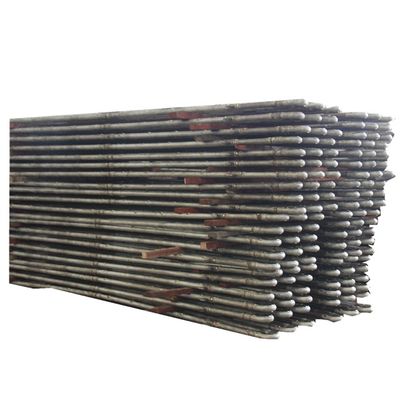

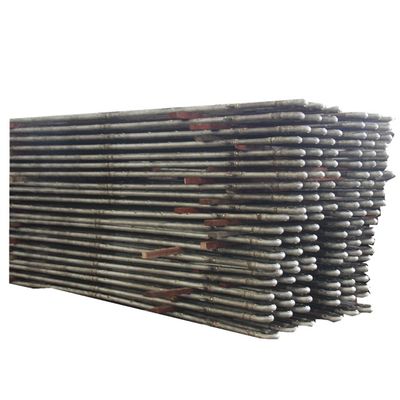

- Economizador de tubos con aletas en H

- Economizador de tubos con aletas en espiral

El economizador de tubos con aletas en H es un diseño particularmente eficiente que consta de tubos con aletas en H. En comparación con los economizadores de tubos lisos, los modelos de tubos con aletas en H ofrecen varias ventajas:

- Mayor área de intercambio de calor

- Menor número de tubos requeridos

- Mayor área de flujo de gases de combustión para disminuir la velocidad del flujo y la abrasión

- Disponible en configuración de tubos con aletas en H dobles para una mayor rigidez en filas de tubos largos

El economizador con aletas en espiral representa nuestra última innovación en diseño, con tubos con aletas en espiral que abordan eficazmente los problemas de abrasión y prolongan la vida útil.

| Descripción | Economizador de calderas |

|---|---|

| Material | Acero aleado, acero al carbono, SA210C, SA213T22, etc. |

| Estándar de material | ASTM, EN o ISO, etc. |

| Dimensión | Personalización |

| Peso | Mín.: 10 toneladas Máx.: 1000 toneladas |

| Proceso de fundición | EF+LF + VD |

| Proceso | Material→Lingote → Laminación en caliente/frío→ Tratamiento térmico (Normalizado+ templado) → Inspección → mecanizado en bruto→UT →2º Tratamiento térmico →mecanizado de acabado →Inspección |

| Estándar UT | ASTM A388 o EN10228, etc. |

- Informe de cálculo de prueba de impacto y resistencia con información de materiales aplicados

- Informe de inspección no destructiva (NDT) al 100% de la placa de acero, el tubo y el electrodo

- Informe de inspección de rayos X, rayos γ y prueba de penetración de líquidos (costura de soldadura) para garantizar la calidad completa de la caldera

- Informe de prueba hidráulica para verificar la presión de trabajo estándar y la seguridad